Paper Packaging Gets 20x Better Barrier

New HyperBarrier coating gives paper-based flexible packaging a massive leap in polyolefin oxygen and moisture barrier — offering EVOH, foil, and metallization alternatives — without ruining curbside recyclability.

At a Glance

- HyperBarrier hits the paper-packaging barrier sweet spot between not enough (poly-coated) and too much (EVOH or metallized).

- HyperBarrier coating protects against oxygen, moisture, and grease.

- For paper-based flexible packaging, this new coating might be able to help you reach your 2025 sustainability goals.

Maybe you can have it all. If you’ve been looking for paper packaging that is curbside recyclable and offers affordable high barrier to oxygen, moisture, and oil with less plastic or chemicals, read on.

The new HyperBarrier monolayer extrusion coating from Smart Planet Technologies checks all those boxes. Chris Tilton, Chief Technology Officer, Materials, and inventor of HyperBarrier, introduced the coating on Tuesday, April 16, to an audience at the TAPPI FlexPack PLACE conference.

What is HyperBarrier? It is a patented and patents-pending ternary nanocomposite coating that provides up to a 20x improvement in oxygen barrier performance and 15x improvement in moisture barrier performance over typical polyethylene coatings in paper-based flexible packaging. Extensive studies back up these remarkable numbers (more on that later).

Who would be interested in HyperBarrier? Anyone who wants to switch from plastic to paper packaging but hasn’t been able to because of paper’s low barrier performance, says Smart Planet Technologies’ President Will Lorenzi.

Obvious key markets are foods and beverages. Coffee, spices, and other retail products looking for more freshness, often found in flexible packaging and sachets. But even pharmaceuticals, detergents, pet food packaging, and personal care products can benefit from the enhanced protection.

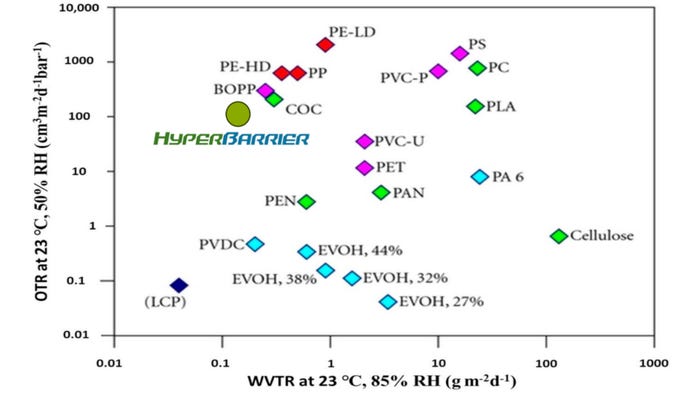

Tilton explains that, for paper and flexible packaging, the barrier options until now have been polyethylene coated (providing low barrier) or expensive multilayer laminations, typically with a layer of foil, ethylene vinyl alcohol/EVOH, or other plastics (for nearly perfect or “ultimate” barrier). HyperBarrier hits a new sweet spot: Very good, affordable oxygen, moisture, and oil barrier. [Click through slideshow to see a larger version of this chart.]

SMART PLANET TECHNOLOGIES

Oxygen permeability (OP) and water vapor transmission rate (WVTR) normalized to a thickness of 100 µm for different polymers. Source: Fraunhofer; HyperBarrier added by Smart Planet Technologies

HyperBarrier’s introduction is opportune for brands working toward achieving their sustainability goals — some by 2025 — says Lorenzi. “Brands, I think, will recognize, ‘Oh my gosh. We can do a lot more with paper than we thought.’ Some of those targets that they didn’t think possible, can now be achieved.”

EarthCoating maximized.

If the description above of the HyperBarrier coating sounds familiar, it’s because HyperBarrier builds on the company’s existing EarthCoating technology. Introduced in 2013, EarthCoating has since been commercialized in more than 2.5 billion packages to date, according to the company, including in flexible packaging.

DETPAK

In Australia, using EarthCoating, potato and onion producer Mitolo Family Farms developed a curbside recyclable paper bag for fresh potatoes with packaging converter Detpak and supermarket retailer Coles. Last month (March 2024), Detpak won the APPMA Packaging Design Innovation Award for this package during Australia’s packaging show APPEX, Australasia’s Processing and Packaging Expo, owned by Australian Packaging and Processing Machinery Association (APPMA).

Tilton says, “HyperBarrier is a separate suite of products retaining all of the advantages of our previous technology, however, with HyperBarrier levels of barrier performance.”

HyperBarrier blends calcium carbonate with nanoclays to create a food-safe coating with a new level of barrier performance. The products are drop-in replacements for existing resins used in paper coatings and in flexible packaging.

The ternary designation refers to the three major components of the layer:

1. Polymer matrix (polyethylene/PE, high-density polyethylene/HDPE, polypropylene/PP, and mixtures of HDPE and PE).

2. Nanoparticles (nanoclay).

3. CaC03 particles (calcium carbonate).

“The CaC03 minerals are larger ‘micro particles’ and can be present up to 40% of the coating,” Tilton says, “thus lowering plastic and providing enhanced paper recycling. The nanoparticles provide extremely high-barrier performance and are evenly dispersed in the matrix with the CaCo3. The nanocomposite compounds are ‘drop in’ replacements for HDPE, PE, and PP.”

HyperBarrier is applied in layer thicknesses from 15 to 75 microns. Tilton explains, “The extremely high-barrier performance lets us greatly reduce the size and mass of the coating layer for paper recycling. Plus, the added CaCo3 further lowers plastic content and again results in great paper recycling performance.”

At this point, HyperBarrier is recyclable, but not compostable. Yet. “Historically, [with EarthCoating,] we started mineralizing PE first, then HPDE, then PP, and then finished with bio polymers. This is also the plan for HyperBarrier,” Tilton says.

Now available commercially, HyperBarrier is produced by paper mill Carvajal Packaging Co. Carvajal Packaging has many converting locations throughout Central and South America. HyperBarrier production is done at the Pamolsa-Lima, Peru, location.

Tilton also tells us that production begins May 2024 for the European Union (EU) at Polibarr, an extrusion coating supplier located in Lithuania.

SMART PLANET TECHNOLOGIES

HyperBarrier is available premixed and as a masterbatch that can be mixed with a customer’s existing resin supply. Annual global capacity for the masterbatch is approximately 280,000 tons of coated paper.

Let’s dig a little deeper into the advantages of HyperBarrier, specifically improved barrier, recyclability, plastic reduction, food-contact safe, cost savings, aesthetics, and machinery considerations.

Improved barrier.

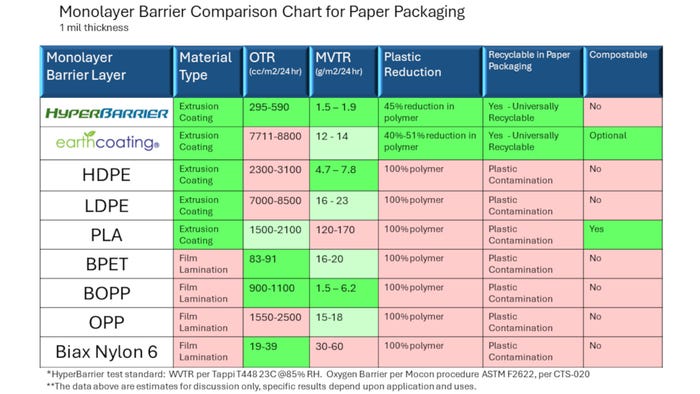

Smart Planet Technologies has done extensive testing to prove the HyperBarrier composites perform as stated: up to 20x oxygen barrier and 15x moisture barrier compared to poly-coated paper. Also, similar to EarthCoating, HyperBarrier shows zero permeation to grease per the 3M Kit test. [Click through slideshow to see a larger version of this chart.]

SMART PLANET TECHNOLOGIES

I’ve seen the following test results, which are proprietary, so I can’t link to them. But as a customer, you would be entitled to see them, too. I’m not qualified to analyze the results, but the numbers do back up the claims.

Independent testing (paid for by Smart Planet Technologies) was done by Applied Paper Technology Inc. and Ametek Mocon. Tests done were:

• Oxygen permability tests by Fraunhofer (see first chart in article above).

• TAPPI T448 Water Vapor Transmission Rate (WVTR) in TAPPI standard lab conditions (50% RH and 73-degrees F).

• TAPPI T441 Cobb Water Absorption on the coated side at 30-minutes, 8-hour, and 24-hour contact time.

• TAPPI T559 3M Kit Test Grease Resistance Rank.

• Heat seal with Sentinel Unit, 2-second compression at 60 psi, to test the conditions to achieve heat-seal bonds coating-to-coating and coating-to-backside of the same material.

Plastic reduction.

Lorenzi emphasizes that, with HyperBarrier, brands can get the barrier performance they need but with a dramatic reduction in plastic for two reasons:

1. Working together, EarthCoating with HyperBarrier technology greatly reduces the plastic content of the package. First, the EarthCoating layer is mineralized from 40% to 51%, removing up to half of the plastic content. Next, the addition of nanoparticles into the EarthCoating matrix greatly improves functional barrier performance. The new high-performance barrier layer now makes is possible to significantly downsize the layer. The reduced plastic content and downsized layer make it much easier to integrate paper into flexible packaging and still meet paper recycling requirements.

2. As mentioned already, brands wanting to replace plastic packaging with paper — but needing affordable high barrier — can now make that switch.

Recyclability.

Packages coated with HyperBarrier are curbside recyclable.

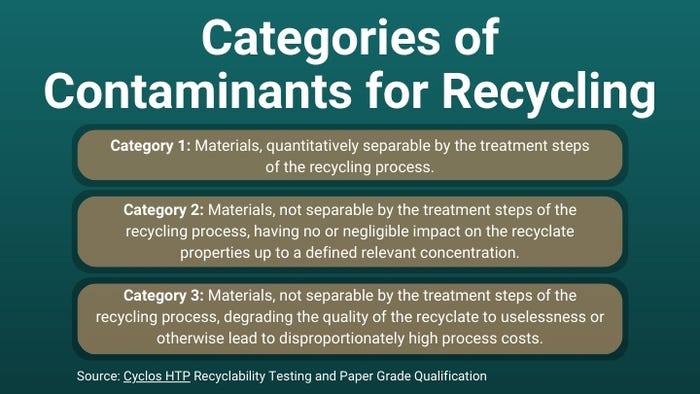

Packaging with EarthCoatings has received Triple A certification from Der Grune Punkt (The Green Dot) in Europe. Additionally, EarthCoating is identified as a Category 2 ingredient — an inert ingredient that does not interfere with processing — according to Cyclos HTP Recyclability Testing and Paper Grade Qualification. Since the barrier coating does not interfere with the recycling process, the packaging was categorized in Path 13 along with uncoated paper for the purposes of recycling.

Testing of HyperBarrier specifically has not been done for Green Dot certification nor for Cyclos HTP grading, says Tilton. “However,” he explains, “it is not necessary because the nano particles are dispersed at very low levels into the existing EarthCoating formulation(s).”

HyperBarrier particles comprise from 2% to 3.5% of the coating and less than 0.005% of the package (coated papers), says Tilton. “Therefore, they do not impact recycling, compliance, or printing of EarthCoating, only providing greatly improved barrier performance.”

Paper recyclers don’t want comingled materials, like paper with poly-coating. The plastic clogs their pressure screens in the centrifical cleaners during the recycling process. As with EarthCoating, HyperBarrier is an inert component in paper recycling and is removed in the same process as clay coating, by gravity. Processability is no problem once the coatings have 38% or higher percentage of minerals. That’s why EarthCoatings have a minimum of 40%.

“In Australia, we’re being collected in office paper. We’re in the highest level of quality materials to recover.”

Lorenzi explains that there are different levels of “recyclable” materials. Paper packaging coated with EarthCoating or HyperBarrier maintain their quality. “In Australia, packaging with EarthCoating has been collected for producing gift wrap for Hallmark, and copy paper for Australian Paper,” Lorenzi says. “Packaging with EarthCoating has proven to be a high-quality material to recover.”

Food-contact safe.

EarthCoatings and HyperBarrier are considered generally recognized as safe (GRAS) from a food contact point of view. Smart Planet Technologies commissioned proprietary compliance and safety studies from a Ph.D. at the University of California, San Diego, which I have seen and can confirm.

EarthCoating has also completed EHS-Compliance safety testing for the EU (the same compliance exists for the US-Food and Drug Administration). Testing was done by J.S. Hamilton Poland S.A. and I’ve seen the results.

Cost savings.

Food and beverage companies select barrier for the worst-case scenario, regardless of what the consumer activity is and the typical turns (sales cycle). That can get expensive. So packaging engineers are always on the lookout for barrier solutions that cost less.

According to Tilton, particularly for moisture, HyperBarrier provides an alternative to products such as polyvinylidene chloride/PVDC, EVOH, and metallization in a low-cost PE and HDPE format that’s efficient, monolayer.

Indirect cost savings come from also saving manufacturing time: extrusion coating is an inline process; laminations require a secondary step.

Additionally, as previously mentioned, brands can buy only the barrier they need instead of paying for overkill because that’s all that’s been available. “This is a whole new option that they didn’t have before,” says Lorenzi.

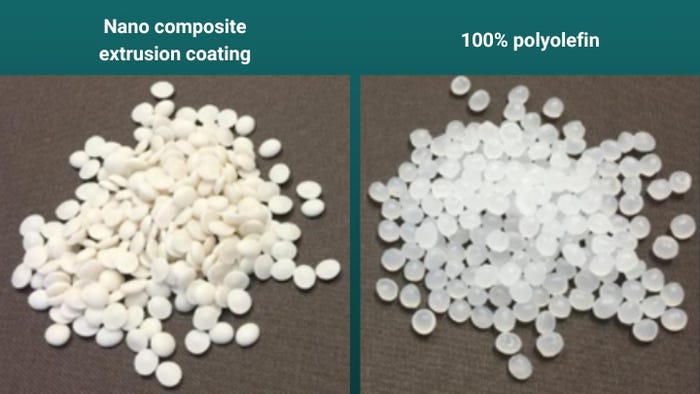

SMART PLANET TECHNOLOGIES

HyperBarrier ternary nanocomposite creates a distinctive “white curtain” during extrusion coating because of its mineralized content, compared to the typical clear curtain of 100% polymer.

Aesthetics.

While not a functional aspect, HyperBarrier has an aesthetic feature worth noting for its marketing value. Unlike 100% polymer coatings, which are clear, HyperBarrier and EarthCoatings, by nature, are white and opaque because the minerals block light. The white coating adds a cleanness to the inside of the package, in my opinion.

EarthCoating customers have found this appealing. So much so that the company has created “Print White” EarthCoating that contains titanium dioxide/Ti02. Tilton says, “Because the EarthCoating is already white and opaque to some degree, it takes much less TIO2 pigment to achieve high whiteness. Therefore, the Print White EarthCoating is very cost effective and yet still maintains recyclability and lowers plastic content.”

Print White EarthCoatings are available with HyperBarrier nanocomposite performance.

“Further,” Tilton says, “the minerals in the coating provide a higher dyne level without corona treatment and also improved ink wettability because the surface has a greater coefficient of friction than PE, for example.”

Machinery considerations.

Speaking of coefficient of friction … do HyperBarrier-coated materials have a different COF when running on the packaging line? “The surface COF of HB is the same as regular EarthCoating,” says Tilton.

“If heat seal is your constraint … for speed, you can actually reduce the dwell time.�”

However, you may be able to run packaging lines at higher speeds because EarthCoating with HyperBarrier has a heat-sealing advantage. As Lorenzi explains, “EarthCoating, for heat seal, actually works better because minerals grab and dispel heat more readily. While we have less polymer, we get better heat seal because more of it activates, and it activates more quickly. If heat seal is your constraint … for speed, you can actually reduce the dwell time.”

The comparison chart above includes heat-sealing data.

According to Smart Planet Technologies, HyperBarrier layers provide high-performance heat seal for use in rigid and flexible packaging.

The biggest takeaway from a machinery point of view is that — other than routine familiarization — HyperBarrier is a drop-in replacement on existing systems, meaning no capital equipment or changes to manufacturing processes are needed for extrusion coaters, converters, or brand owners. Tweaks, maybe, but nothing else.

“Unthinkable” breakthrough.

Sustainability is still the No.1 trend in packaging for brand owners. Consumers, especially younger ones, consider a company’s environmental position and actions before buying a product.

But products that need high barrier have been at a disadvantage because the packaging technology didn’t allow for less complex structures.

With HyperBarrier, Smart Planet Technologies touts “previously unthinkable environmental paper-based flexible packaging applications.”

Tilton and Lorenzi are understandably proud of this development. Lorenzi calls Tilton a “packaging engineer extraordinaire” with “incredible capability” for invention. And aren’t some of the most-effective inventions are the ones that seem so simple and obvious — after the fact, of course.

Tilton says the best solutions are often based upon new technologies and materials that take performance to the next level — giving packaging engineers dynamic and previously unavailable tools when designing for a better environment.

Lorenzi says, “So much packaging can be switched over from plastic to paper when you have this kind of performance — and so affordable in a single monolayer extrusion coating.”

About the Author(s)

You May Also Like